Drill string design is. Slip Crushing Slips exert hoop compression on the drill pipe which can deform the pipe if conditions are unfavorable.

Drill String Design Lecture Notes 12 45 Drill String Design The Following Topics Will Be Studocu

Stuck point calculations for drill string weight jar placement.

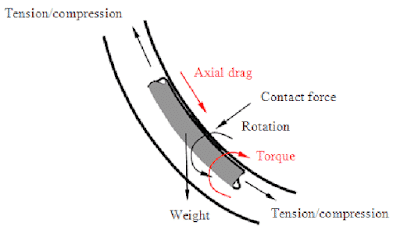

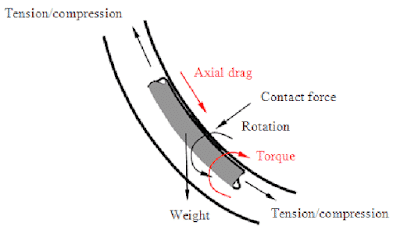

. Torsion tension ensuring that the stresses produced do not exceed the components yield strength. Test equipment mechanical limits. 30 Full PDFs related to this paper.

EVALUATION OF TECHNICAL DRILLING OPERATION CASE STUDY IN INDONESIA. This 5-day course will address all elements of drillstring selection and design integrating drilling optimisation with drillstring failure prevention. Objectives Assumptions and Factors Part-04 31 ObjectivesThe objective of drill string design is to.

The participants will learn about the drill pipe grade the limitation for torque and tension and the drill collars tensional stress. The training Timing will start be agreed according to your group nationality. Drillstring Design Set a training goal and easily track your progress In just few simple steps you can customize your own learning journey in the discipline of your interest based on your immediate intermediate and transitional goals.

Once done you can save it in NExTpert the digital learning ecosystem and track your progress. Selecting items from a list of ready-made components not deciding what an individual component will look like. Drill string design course Nail artwork inspires Everybody.

The course provides a comprehensive treatment of drill string design as well as the avoidance of operational problems and wear on equipment following the API recommended practices for design and operating limitations. We are constantly updating our materials to reflect the latest technology applications for both near-vertical and high-angle well designs while maintaining a thorough grounding in the fundamentals. A short summary of this paper.

Full PDF Package Download Full PDF Package. We have been presenting Drill String Design workshops for over 12 years for all types of operations around the world. Drill String Design August 27 2020 As drilling engineers we are often involved in optimising the drill string design to improve tensile torsional and hydraulic performance.

Course About the Course We have been presenting Drill String Design workshops for over 12 years for all types of operations around the world. Have a technical overview of all operational and technical aspects required to design and operate drillstring equipments in complex drilling programs. It clarifies the performance properties of drill string components and explains how to apply design margins.

All online courses will be through zoom or any other application. Drill String Design 000 EGP. It is easy to be done just remember dont exceed 80 of drill pipes yield strength.

Drill string design process is placed in context with other planning and operational considerations of well planning. The following design factors shall apply when designing a. SPEC Q1 API Awareness.

Capture experience. Tag drill string design course Drill String Design. However all too often we leave drill-pipe inspection to the QAQC department.

PETER AIRD CEng CMarEng MIMarEST is a specialized drilling consultant based in Fife Scotland. This 5-day course will address all elements of drillstring selection and design integrating drilling optimisation with drillstring failure prevention. This course has passed.

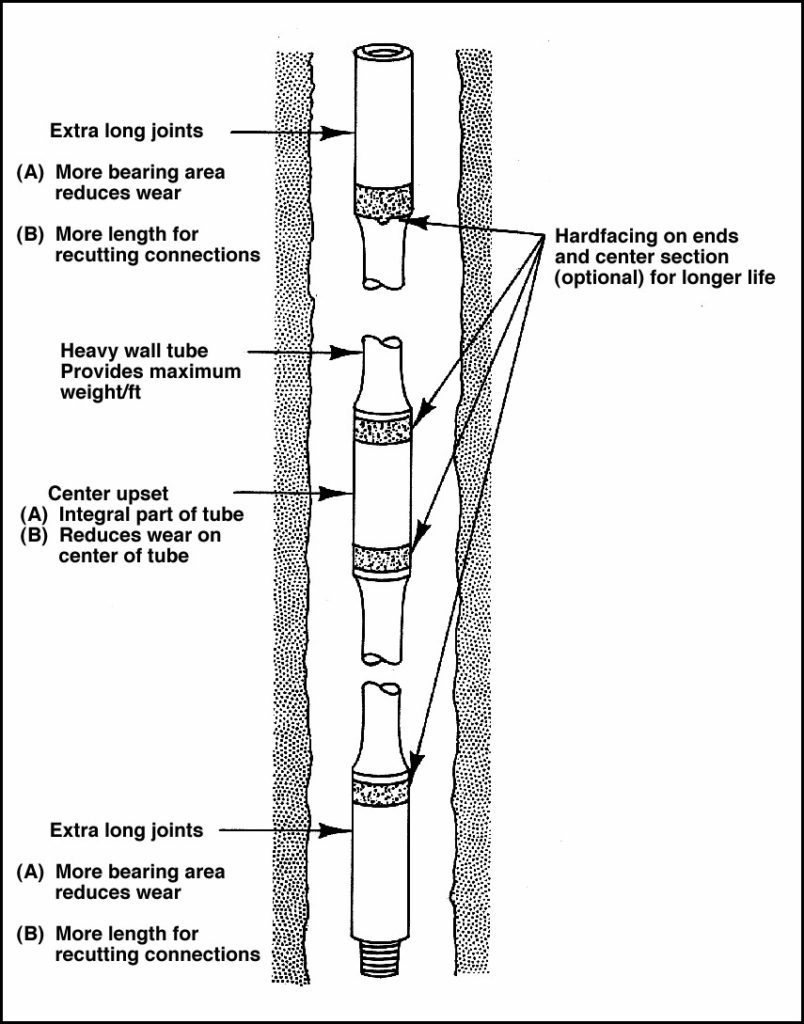

Non-magnetic steel for survey instrument Drill String Accessories Heavy-wall drill pipe Has the same OD of drill pipe and reduced ID Used between DP and DCs Manufactured in four sizes. SPEC Q1 API Internal Auditor. SPEC Q1 API Lead Auditor.

We are constantly updating our materials to. Download Full PDF Package. He formed Kingdom Drilling Services Ltd in 1993 to provide well design engineering and drilling operations training and consulting to serve an extensive list of operating and national oil clients worldwide Shell BP Conoco Kerr-McGee Marathon Maersk Oil Total.

Drill string design needs from you to check the maximum over pull you can apply to drill string without drill pipes failure. Participants will learn about the mechanical properties of all drillstring components including their connections both as individual pieces and when made up into a drillstring. This drilling string design program is a unique course discussing all factors that influence the drill string during operations.

SPEC Q2 API Internal Auditor. The course starts with refreshing the engineering fundamentals and. In doing so are we increasing the risk of failure on our wells.

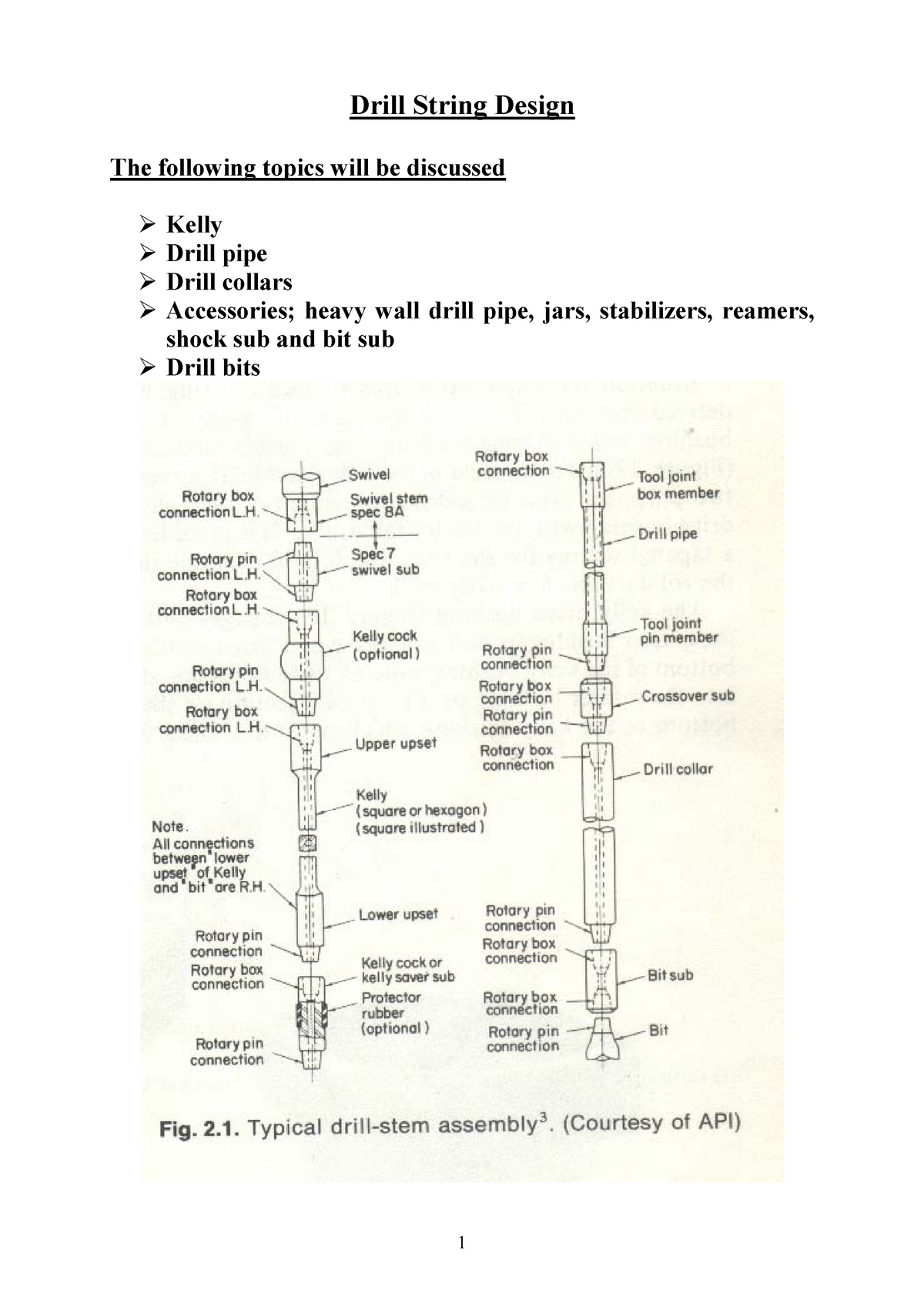

It refreshes hidden physics of drill string failures and mechanical properties of drill string materials. Delegates will be able to optimize the drilling operations by performing a proper. Topics covered include vertical and deviated well string design selection of BHA.

ISO 90012015 Internal Auditor. This course is divided into 5 sections as. Peter Aird X MR.

It examines the refinery system and functions alongside equipment and the role of the refinery operator. Q1 Q2 Courses. SPEC Q2 API Lead Auditor.

The course provides a comprehensive treatment of drill string design downhole drilling dynamics and the avoidance of operational problems and wear on equipment following the API recommended practices for design and operating limitations as well as the standard DS1 for design and inspection. Selecting components that are able to withstand the combined loads applied during drilling operations eg. SPEC Q2 API Awareness.

Drill String Design CourseAbsorb vibrations and impact loads caused by drill string movement steel rubber spring design to absorb torsional and vertical vibration placed normally above the bit stabilization requirement dictate placement 30 to 50 above the bit drill string design design means determination of length weight grades of drill pipe to be used during drilling coring or. Drilling Engineers Drilling Supervisors Junior Directional Drillers Senior Drilling Engineers Tool Pushers Purpose. Choose the right equipments for non-conventional extreme drilling.

ISO 90012015 Lead Auditor. Ensure that the maximum stress at any point in the drill string is less than the down-rated yield strength Ensure that the components and configuration of the drill string.

Torque And Drag In Drilling Calculations Spreadsheet Drilling Manual

Procedure To Design A Hand And Foot Lever Dragonfly Education Educational Videos Machine Design Design Course

Basics Of Drill String Design Skillsupload

Basics Of Drill String Design Skillsupload

Basics Of Drill String Design Skillsupload

Bottom Hole Assembly Bha Components And Design Drilling Manual

0 comments

Post a Comment